Press Brakes & Shears Controls

Retrofitting a shear or press brake begins with a thorough evaluation of the machine’s construction—including its hydraulic system, backgauge, axis, crowning system, punch holder, and more. These factors reveal both the capabilities and potential drawbacks that must be carefully considered when upgrading the machine to meet current needs and future demands.

The next step is selecting the right controller. Typically, there are at least two different controllers in each case. The chosen controller serves as the platform that integrates the original machine accessories and facilitates future upgrades.

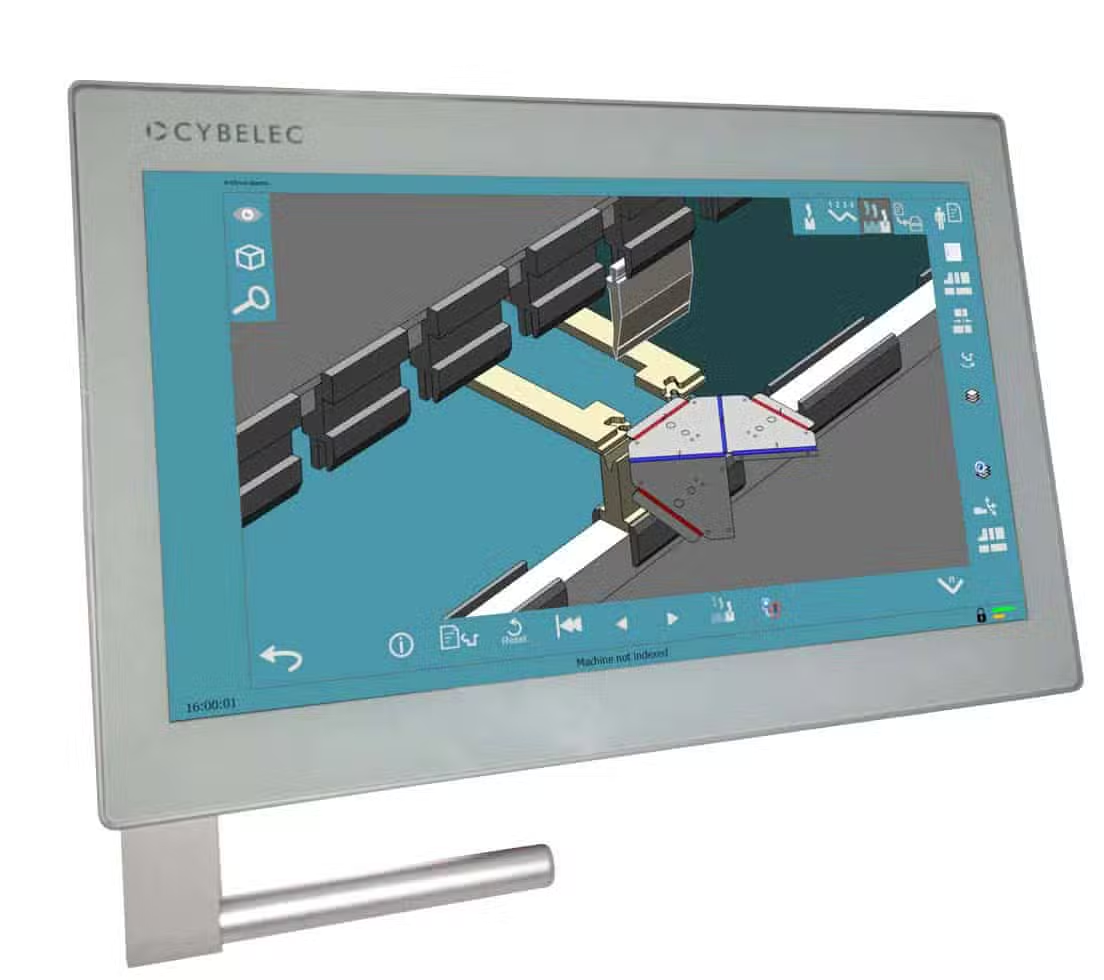

Press brakes CybTouch PS Series

CybTouch 15 Win

- 15’’ Glass Touch Screen

- Max. 6 Axis

- 2D Graphic and 3D viewer

- Windows 10 for networking and remote maintenance.

- Industry 4.0 ready.

Press Brakes VisiTouch Series

VisiTouch 19

- 19’’ Glass Touch Screen

- Max. 26 Axis

- 2D Graphic and 3D viewer

- Windows 10 for networking and remote maintenance.

- Industry 4.0 ready.

- Support Angle Measurement and Other Press Brakes peripheral systems upgrades .

- Support Robot Cell Retrofit Solutions

VisiTouch 19 MX

- 19’’ Glass Touch Screen

- Max. 26 Axis

- 2D Graphic and Advanced 3D graphics

- Windows 10 for networking and remote maintenance.

- Industry 4.0 ready.

- Support Angle Measurement and Other Press Brakes peripheral systems upgrades .

- Import of DXF/DWG, IGES, STEP, SAT and X_T

- Support Robot Cell Retrofit Solutions

VisiTouch 24

- 19’’ Glass Touch Screen

- Max. 26 Axis

- 2D Graphic and 3D viewer

- Windows 10 for networking and remote maintenance.

- Industry 4.0 ready.

- Support Angle Measurement and Other Press Brakes peripheral systems upgrades .

- Supporting Robot Cell Retrofit Solutions

VisiTouch 24 MX

- 24’’ Glass Touch Screen

- Max. 26 Axis

- 2D Graphic and Advanced 3D graphics

- Windows 10 for networking and remote maintenance.

- Industry 4.0 ready.

- Support Angle Measurement and Other Press Brakes peripheral systems upgrades .

- Import of DXF/DWG, IGES, STEP, SAT and X_T

- Support Robot Cell Retrofit Solutions

Shears CybTouch Series

CybTouch 8 W

- 8’’ Glass Touch Screen

- Swing Shears.

- Front or back gauge management.

- Automatic blade gap or cutting angle.

- Sheet support.

CybTouch 8 G

- 8’’ Glass Touch Screen

- All types of Shears.

- Front or back gauge management.

- Automatic blade gap or cutting angle.

- Sheet support.

CybTouch 12 G

- 12’’ Glass Touch Screen

- All types of Shears.

- Up to 4 front or back gauges management.

- Automatic blade gap or cutting angle.

- Sheet support.

Offline Software Solutions

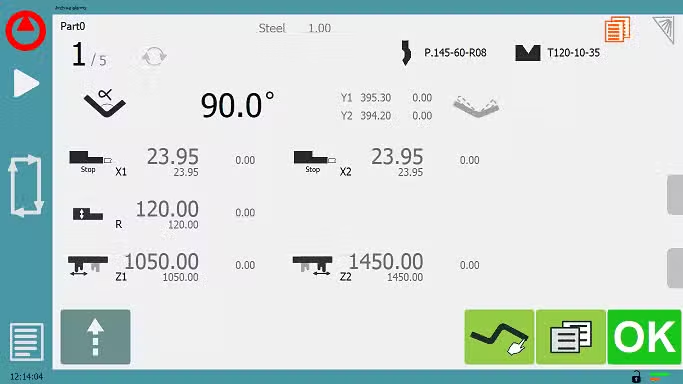

VisiTouch Offline

Your press brake controller on your computer lets you prepare your bending parts and analyze bending sequences in an easy, efficient manner. Select tools, program parts, define bending sequences, simulate in 2D for collision checks, and send job programs to your press brake.

The offline PC software, VisiTouch, will transfers tools and programs to all CybTouch and VisiTouch controllers.

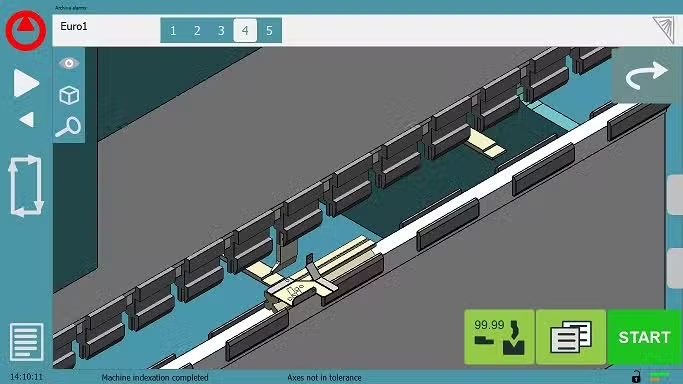

VisiTouch MX Offline

VisiTouch MX is an offline 3D VisiTouch Controller that runs directly on your computer, loaded with your machine parameters while adding advanced 3D capabilities. Its state-of-the-art graphics enable you to solve complex bending sequences, as the 3D environment accurately handles polygonal and non-linear geometries and fully leverages the potential of back gauges—especially those with more than four axes.

VisiTouch MX lets you quickly and efficiently import and unfold 3D files, automatically determine optimal tooling and bending sequences, and dynamically simulate the entire process in 3D to check for collisions. Supporting file formats such as DXF/DWG, IGES, STEP, SAT, and X_T, this PC offline software will transfer tools and programs to all CybTouch and VisiTouch controllers.